Today, we spoke with two employees of Schneider Electric, a company specializing in supplying low and medium voltage electrical equipment and industrial automation. Matthieu Mailly, Global Circular Economy Transformation Manager, and David Potier, Sustainability Manager within Global Supply Chain Europe, work together on a program dedicated to the Circular Economy. In this interview, they share an overview of their circular activities, which have been anchored within the company’s ethos for more than 20 years, as well as the new challenges associated with them.

1. What is Schneider Electric’s position on the Circular Economy?

Circularity has been present at Schneider Electric for about twenty years. At the time, we initiated a program in response to the specific needs expressed by a customer. The aim was to give them access to spare parts so that they could repair various industrial products. The term “Circular Economy” had not yet been coined, but in fact, that’s exactly what it was. Today, this offer is more relevant than ever. We’ve even expanded this program by creating a dedicated repair service.

Since then, we structured our systems by integrating a circular approach at all stages of our products‘ life cycles.

2. How does this translate operationally throughout the life cycle of Schneider Electric products?

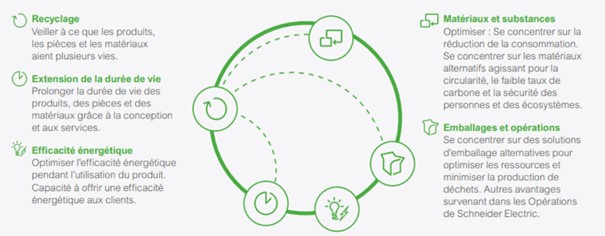

We are not talking about a recycling economy, but rather an economy of materials and resources. For our products, this translates into several stages that are activated successively throughout their lifespan:

- Eco-design principles, namely designing products with fewer materials and using materials from environmentally friendly sources. The manufacture of these eco-designed products also requires less energy and their environmental impact is reduced throughout their life cycle. Eco-design is the cornerstone of the Circular Economy for all new products to come.

- Maintaining products in operational condition;

- Reuse resources, through:

- Repacking, which consists of recovering products never used, verifying their condition, and putting them back on the market;

- Refurbishing, which consists of recovering products already used by customers and then restoring them at our factories and putting them back on the market.

- Finally, recycling should only be used as a last resort.

Since 2023, Schneider Electric dedicated a department towards advancing the Circular Economy. We have even launched our own labels to reinforce our approach, such as “Checked & Repacked by Schneider Electric,” for repackaging and “Refurbished by Schneider Electric” for reuse. The company’s significant investment in the Circular Economy currently involves around a hundred people: we are moving from a period of innovation to a real operational transition for the future!

3. How do you select the products involved in the Circular Economy and pick the “right battles” when it comes to your diverse range of products and components?

In the context of eco-design, all our products are concerned with identifying the materials used and applying internal repairability indexes (although these are not mandatory in our industry). Our R&D centers around the world are up to the challenge when it comes to all of our new products. The potential for product recovery (or “take back”) within refurbished offerings is also a key criteria for how we select products for this program.

Knowledge of our designs, product life cycles, and the potential for recovery of our products thus makes it possible to identify the relevant ranges. To determine the “right battle,” it is necessary to identify the potential of an available material in a very pragmatic way.

4. What are the criteria defining a “good” eco-designed product? How do eco-design ambitions influence innovation and possible additional costs?

A product is considered to be ecodesigned “well” when it meets five criteria:

- It only has recyclable parts;

- It has energy efficiency functions compared to equivalent products on the market;

- It does not contain any hazardous substances;

- It has good repairability criteria;

- It has connectivity functions that allow predictive maintenance alerts to be sent.

The eco-design revolution asks us to think of each product as a set of functions. Each function is a mechanical brick that can be disconnected from the others and must be easily detectable, repairable, and interchangeable. This poses real challenges in terms of connections between these different functions. The long-term objective would be to push this technology to the end user, enabling them to become autonomous regarding product repairs.

The Circular Economy is based on the fusion of the product and service worlds. The additional costs generated by a modular product can thus be offset by the sale of this service, post-purchase. Of course, it is also necessary to integrate the level of market acceptability, overall profitability, and apply common sense so that the overall environmental footprint of repairing a product is not greater than replacing it with a new one.

5. What’s your strategy in regard to recycling, which was mentioned earlier as a last resort?

Recycling involves two main issues:

- The supply of recycled materials from our partners;

- Recycling waste from our sites: the “Waste-to-Resource” program label encourages all our sites to recycle at least 99% of their waste and transform it into new resources.

We are more interested in the link between circularity and resilience to work on the most critical materials. Resilience goes beyond recycling, allowing us to retain ownership of certain strategic materials and guarantee their traceability. There is a real challenge in retaining ownership of our production waste especially in terms of sensitive and critical materials. We are therefore emphasizing the adoption of a resilient circular model that is not based solely on recycling.

6. How do you manage the data related to monitoring the product life cycle?

Managing data related to the Circular Economy can be a challenge. Today, a product can go through several states during its life cycle (damaged, reused but functional, repaired, remanufactured, etc.)—with varying degrees of traceability. This requires a solid structure for a market that is still quite niche. We must remain engaged and mobilized to achieve results. The skills are certainly there, but we need to change mindsets so that stakeholders are open to different ways of thinking.

We have made good progress over the last two years on IT and data transformation, but it required a lot of time and resources. For manufacturers who are just starting out, this is not a subject to be minimized in terms of overall investment!

7. How do sales teams and customers perceive products from the Circular Economy?

Our customers are very sensitive to the issue, and the issue itself is very sensitive! First, we have set up teams dedicated to the marketing of our Circular Economy offers, which will train sales representatives in the field. Our objective is that they can explain our offer and the new practices that we have developed.

The Circular Economy is a real need within the industry. For example, the French construction market is extremely engaged in the Circular Economy. Some of our clients in this field share their forecasts and roadmaps on the Circular Economy with us.

The COVID19 pandemic played a pivotal role in the development of the circular market. From 2020 onwards, product supply disruptions made this kind of initiative essential. Ultimately, customer satisfaction with these circular products enables these practices to continue and expand.

8. Finally, what obstacles might there be today to your company’s commitment to the Circular Economy?

First of all, the normative and legislative frameworks (standards, ISO, labels) are limited at the moment. We need a strong framework to structure companies in this field. Even in terms of vocabulary, the definitions of each term are not yet correctly defined or comprehensive.

A second obstacle is the need to bring about a shift in mindset among our customers and partners. This change, both internally at all levels of the organization and externally, is essential to align all industry stakeholders around these new practices. The Circular Economy is more than simply waste management. Understanding this fully will accelerate industry adoption, prompting our customers to evolve, and show the value of circularity.

It is a global transformation that requires investment, including an investment in time and skills. We need to reinvent our models, the entire product life cycle, our customers‘ habits, the digital experience, and even our taxation. That is why it is important that this change be instilled by influential entities, such as the COMEX (Executive Committee), given that this transformation involves new economic models and numerous investments without an immediate return on investment.

Finally, the Circular Economy is limited by competition with the Waste Management Economy. The existence of a parallel Waste Management market is a real obstacle to “take-back.” Waste management companies have no interest in extending the lifespan of products and optimizing resource management, which directly deprives them of their source of income.

9. In conclusion, what would accelerate the potential of circularity today?

Currently, we lack a facilitating legislative and normative framework. Everyone needs to be aligned with clear standards and legislation using the same language. The big challenge for manufacturers is to apply the Circular Economy at a high level and in a certified manner.

The potential for product recovery, at any stage of the product life cycle, remains limited. The ultimate goal would be for the term “waste” to simply no longer exist. Even at the end of their life, all products or components must become resources again, thus making the Circular Economy truly… circular!

Matthieu MAILLY

Global Circular Economy Transformation Manager at Schneider Electric

David POTIER

Sustainability Manager within Global Supply Chain Europe at Schneider Electric